High concentration of precious metals

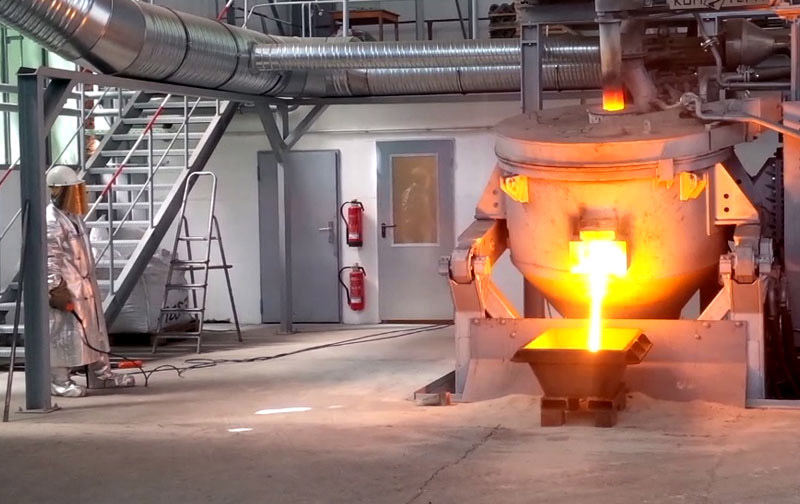

Since 2014 ReMetall Deutschland owns a state of the art smelting shop.

Equipped with an electric arc furnace, enabling us to smelt precious metal monoliths at 1500 degrees Celsius. At such temperatures the ceramic carrier substance liquefies, allowing for the extraction of all metal contents.

In this process the precious metal content of the base material multiplies by a factor of 35. To clarify even further- the precious metal content of a 1000 Kg ceramic base is smelted into 30 Kilograms worth of a precious metal/ iron alloy. This concentration procedure is an essential prerequisite for the chemical separation of the precious metal from its iron base.

The smelting process was thoroughly monitored and researched over the course of a three year study, leading to the implementation of a series of technological innovations, guaranteeing upmost cost efficiency while simultaneously reducing smelting induced losses of material.

The smelting shop has a yearly capacity of approximately 1000 tons of ceramic material. We offer the production of collector metal as a toll processing measure.