Metal Catalysts: clean separation – high profits

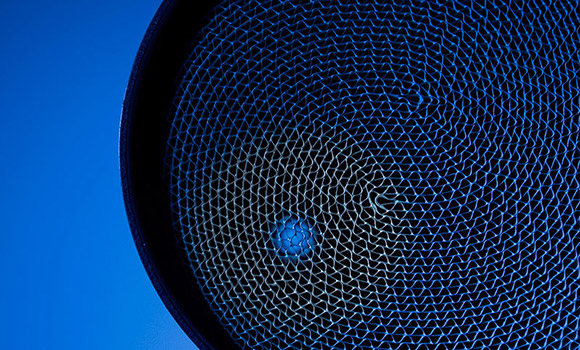

Metal catalysts end up in the recycling process in ever increasing numbers. They offer an alternative to ceramic catalysts not only in vehicles but in numerous other fields of application as well. The comparatively small thickness of their cell walls, achieved through the usage of spiral shaped metal foils and stacked plates as carriers for the precious metal coating, is only one of their numerous advantages.

ReMetall has developed a highly refined procedure, which, through clean separation, allows for significantly above average recovery quotas. We open the catalyst’s casing by hand to extract the precious metal coated foil. The foil is cut into pieces and ground into a fine powder. We extract all precious metal content via suction during the grinding process and create a homogenous metal powder. Following the extraction of probes for value analysis, the material is sent to the refiner for the final processing stage.